- Homepage

- Brand

- Clark Drain (6)

- Eco Deck Grids (8)

- Eco-baeerss (19)

- Eco-worthy (33)

- Eco500 (32)

- Ecodeck (225)

- Ecodeck Ecodrive500 (28)

- Ecodrive (9)

- Ecogrid (167)

- Ecopark (32)

- Ecotree (25)

- Ezy-paver (8)

- Freerangedesigns (12)

- Gucci (14)

- Handmade (61)

- L*space (10)

- Rocketbook (34)

- True Products (31)

- Weird Fish (9)

- X-grid (39)

- Other (396)

- Isbn

- Material

- 100% Cotton (5)

- Cotton (7)

- Eco Terracotta (23)

- Gravel / Chippings (17)

- Hdpe (3)

- Hdpe & Pp Mix (8)

- Metall (3)

- Mix Fabric (8)

- Monocrystalline (3)

- Plastic (221)

- Polyester (5)

- Polypropylene (13)

- Recycled Material (6)

- Recycled Materials (2)

- Recycled Plastic (66)

- Recycled Plastics (2)

- Recycled Polyester (3)

- Terracotta (5)

- Wood (19)

- Wool (16)

- Other (763)

- Size

- Sub-type

- Type

- Area Rug (25)

- Bases (7)

- Berber (27)

- Border (9)

- Bottom (7)

- Building Base Kit (11)

- Deep Cycle (25)

- Eco Paving Grid (7)

- Filter Media (9)

- Garden Sheds (28)

- Grid (282)

- Grids (14)

- Ground Support (8)

- Log Cabins (7)

- Paving (50)

- Plastic Garden Base (6)

- Rug (8)

- Shed Base (33)

- Solar Panel (25)

- Solar Panel Kit (14)

- Other (596)

Plastic Gravel Grid for Shed Bases, Drive Ways and Paths Made In England

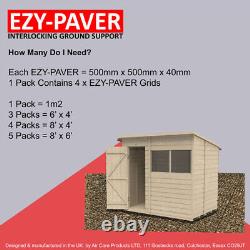

EZY-PAVER is a new innovative ground reinforcement and stabilization product for use in the permanent reinforcing of soft ground providing a stable base for sheds, greenhouses, summer houses, etc. EZY-PAVER is also ideal for the movement of parking of vehicles and for stabilizing soft earth banks. EZY-PAVER is a modular, open design grid tile, manufactured from 100% recycled material. It is tough, flexible, easy to install and allows natural drainage.

1 Pack Contains 4 x EZY-PAVER Grids 100cm x 100cm (Each EZY-PAVER = 500mm x 500mm x 40mm). Fast & Easy To Install. High Load Bearing Base System.

Easily Cut To Fit Any Size Of Base. Fill With Grass, Gravel Or Leave Emply To Create Good Airflow.How Many Do I Need? Each EZY-PAVER = 500mm x 500mm x 40mm.

1 Pack Contains 4 x EZY-PAVER Grids. 3 Packs = 6' x 4. 4 Packs = 8' x 4. 5 Packs = 8' x 6. To find out your how many EZY-PAVER packs are required for your chosen shed base size, simply convert the square footage to meters squared and chose the required quantity from the drop down menu.

The method of installation is determined by existing ground conditions as well as the end use and weight loading requirements. The methods described below provide general guidance only and do not form part of any contract with the user. Prior to use the EZY-PAVERs should be stored to prevent excessive mud, wet concrete or other damaging materials from coming into contact with and affixing to the EZY-PAVER Base. The grid structure can be filled with different materials such as soils (to support plant or grass establishment) or gravel / aggregates. The tiles have a simple male and female interlocking connection.Begin at the furthest away point, laying the tiles from right to left. Ensure that the male connectors face towards you and the female away from you. Installation with no fill is ideal where the product is being covered with a static building or leisure item. For best results ensure the area is level and reasonably well compacted.

This can be done with a roller or by simply removing any loose soil to get to a firm surface below. The better the surface is prepared the better end result you will achieve. For pedestrian use to make a feature stone pathway, then excavation is not necessary. However if this is for a driveway where vehicles are regularly moving over the grids it is advisable that the ground below the grids is firm and has no soft spots. It may be necessary to remove soil and replace with stone or hardcore which can be compacted.A geotextile weed control can be added. The grids can then be connected on top of the textile and filled with a sharp angular stone or aggregate. For a healthy grass infill we recommend the use of a geotextile over a thin layer of stone (10 to 15 mm) to allow for good drainage. The grids can be laid on top and filled with a good soil mix to help the growth of the grass and protect the root or seed. For a quicker installation for noncommercial or private dwellings, you can simply remove enough soil to lay the grids using the existing ground level without the need for stone.

However, the ground may shift in time requiring re-installation. These installation instructions are recommendations to achieve the best results. The grids can sink into the ground if the ground is initially very soft and wet. For large order quantity's & trade.